Various applications, including heavy-duty equipment and agricultural applications, rely on heavy-duty hose clamps. Vermatic has been delivering superior-quality heavy duty hose clamps since 1980. Our clamps are made in the USA and can be standard or custom-made to your specifications while maintaining rapid delivery times.

Learn more about heavy-duty hose clamps and the evolution of their design over the years below.

What Are Heavy-Duty Hose Clamps?

Heavy-duty hose clamps are engineered for challenging conditions and high-pressure applications. They are composed of materials like steel and include polypropylene cushion inserts to deliver corrosion resistance and enhanced strength.

Vermatic’s heavy-duty hose clamp types include:

- Multi-Line Clamps. These user-friendly and effective clamps protect and organize pipes, tubes, or hoses.

- Single Beta Clamps. Vermatic’s 100 Series single clamps come in stacked, double, and single assemblies for various sizes and applications.

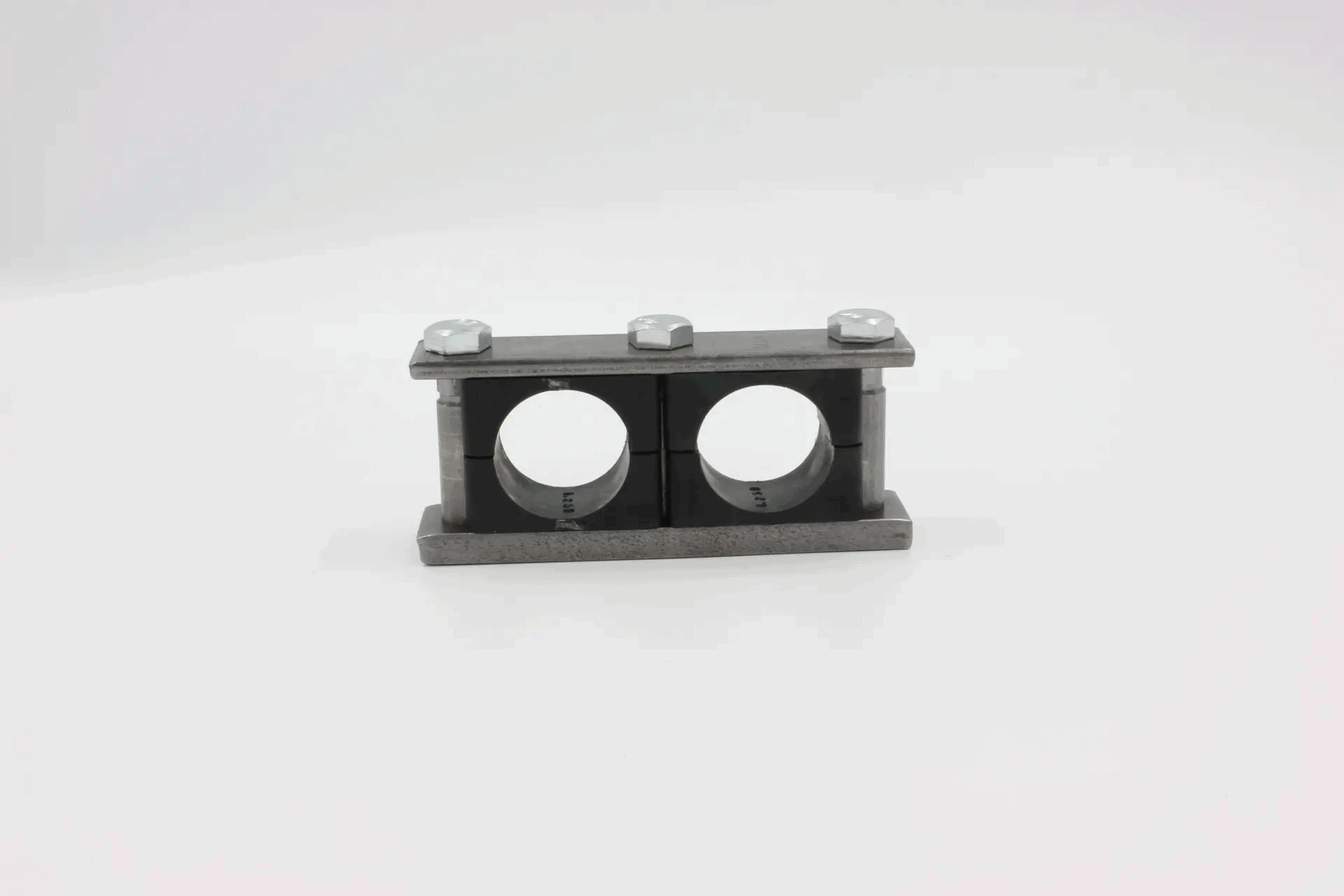

- Twin Clamps. These lightweight, compact clamps protect and secure two pipes, hoses, or tubes. The clamp fastens via a single center-placed bolt for a simple, durable design.

OEMs can choose from a range of custom and specialty clamps for hoses, tubes, and pipes when they partner with Vermatic.

The Evolution of Heavy-Duty Hose Clamp Design

The Industrial Revolution in the 18th and 19th centuries allowed for the development of strong metals like cast iron for use in robust screw clamps and C-clamps. These clamps offered improved durability and clamping force compared to previous designs.

Post-Revolution (20th Century & Early 21st Century)

This time period saw the adoption of high-strength steel enhanced clamp capacities. Trigger clamps and spring clamps were developed, delivering quick one-handed operation. Advanced welding techniques were used to make forged clamps and secure band clamps for high-pressure hoses.

As efficiency became a major focus in the late 20th and early 21st century, the popularity of quick-release mechanisms grew. This enabled rapid operation of hose clamps with an ergonomic design that reduced fatigue and enhanced user comfort. Manufacturers also began to adopt specialty materials (such as composite resins and nylon) to create lighter clamps with adequate corrosion resistance.

Modern Era (Present Day)

Modern hydraulic clamps offer advanced features such as extensive clamping force for securing hoses, tubes, and pipes in demanding industrial applications. Some manufacturers now integrate safety features like pressure relief valves and locking mechanisms for safe and effective performance in critical applications.

The Future of Hose Clamp Design

In the future, we can expect material advancements that continue to allow for the production of lightweight clamps that offer superior strength. Integration with automation and robotics systems can increase clamping performance in complex operations.

How Is Vermatic’s Clamp Design Different?

Customization Capabilities

We work with customers to develop and produce stock and custom clamps that meet exact specifications. Our cushions provide a flat surface to evenly support your hose, pipes, or tubing. Even surfaces prevent water from collecting in the cushion’s profiled areas.

Vermatic’s most versatile clamp line features evenly-spaced posts on the exterior to secure the cushion in place, making installation simple as you build your system design. These posts can be mixed and matched with hose, pipe, and tube cushion inserts to fit the needs of your application.

Material Expertise

We use our extensive material knowledge to select ideal materials for your application. We can ensure your clamps offer optimal corrosion resistance, strength, and compatibility for fluid transfer. Our high-performance materials include:

- Aluminum

- Stainless steel

- Clear zinc

- Black oxide

- Nylon

- Rubber

At Vermatic, we rely on state-of-the-art manufacturing techniques to produce our clamps. Customers can enjoy superior quality, reliable performance, and dependability in products over a longer life cycle.

The Vermatic Advantage: Benefits You Can Trust

- Enhanced Performance. We design our clamps to deliver exceptional sealing and high-pressure performance for safe and efficient fluid transfer within your system.

- Improved Efficiency. Our clamps are designed for fast and simple installation to minimize assembly and maintenance downtime.

- Long-Lasting Durability. We deliver superior wear, tear, and corrosion resistance to maximize your clamp’s lifespan while reducing maintenance requirements.

Quality Heavy Duty Hose Clamps by Vermatic

Vermatic offers a variety of heavy-duty hose clamps made from superior materials with precise manufacturing and quality control. With over 40 years of experience, we continue to serve clients in numerous industries. Request a quote to speak with an expert about our made-in-the-USA clamps for your application.